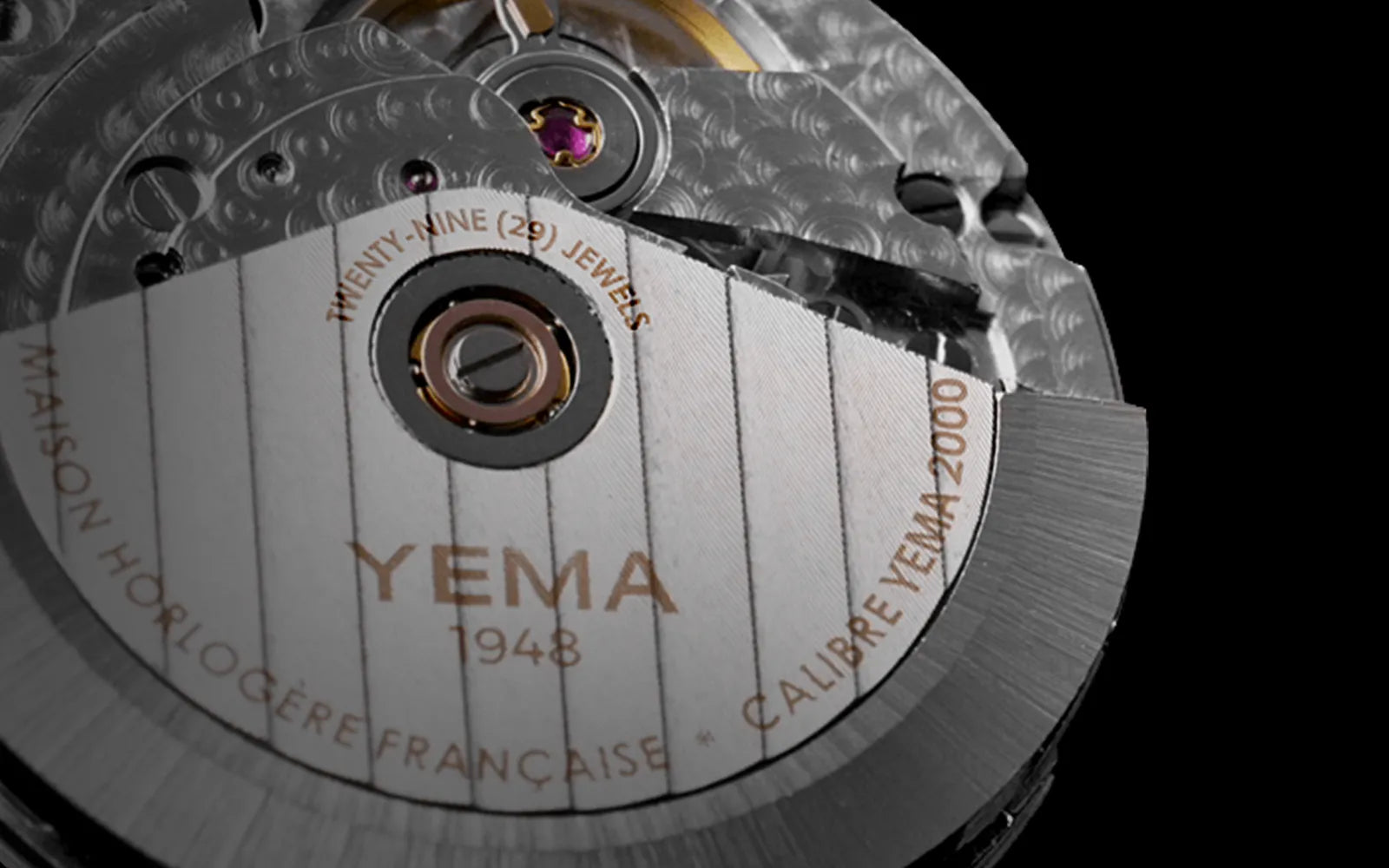

FRENCH MANUFACTURE CALIBER

Caliber designed and developed by Olivier Mory. Micro-components (bridges and mainplates) manufactured directly in our YEMA workshops in Morteau, including assemblies, adjustments and checks.

TOURBILLON TIDE COMPLICATION

Prestigious caliber offering high performance thanks to its clever architecture and high-quality Franco-Swiss components. Unique lunar time complication with display of tide cycles.

-3/+7 SECONDS ACCURACY

Optimised mechanical accuracy with near chronometer-certified performance.

105 HOURS POWER RESERVE

Increased power reserve thanks to a large barrel allowing optimized winding.

MOVEMENT

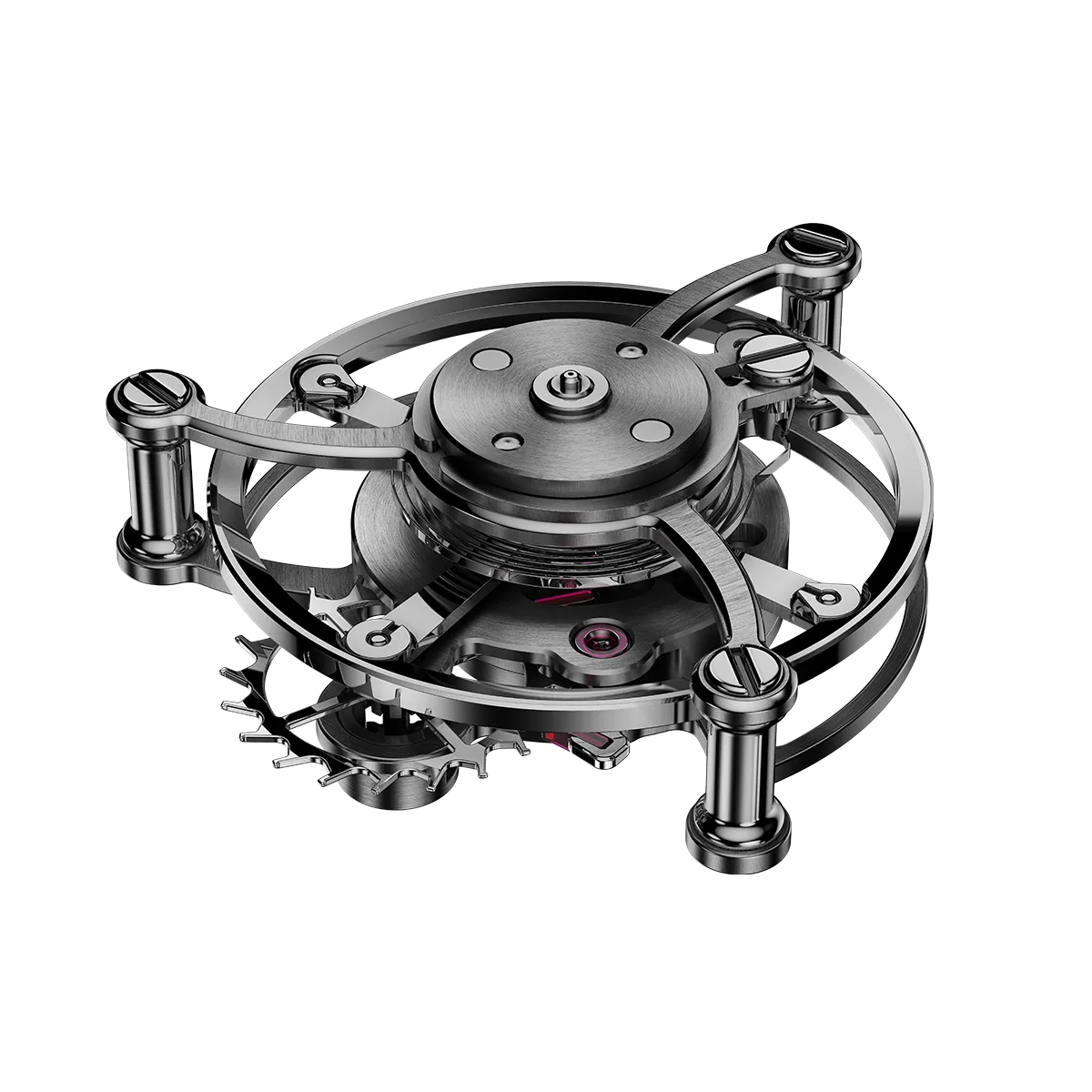

Ø 31mm mechanical hand-wound tourbillon, free-sprung balance wheel

COMPLICATIONS

Tidal cycles

(Lunar time)

FREQUENCY

3Hz (21 600 A/h)

POWER RESERVE

105 Hours

ACCURACY

-3 / +7 seconds

(Adjusted in 6 positions)

MAGNETIC RESISTANCE

2 000 Gauss

SHOCK RESISTANCE

5 000 G

REGULATING ORGANS

Tourbillon cage with free-sprung balance wheel

ESCAPEMENT

LiGa anchor and escapement wheel

JEWELS

19

COMPONENTS

130

DECORATION

ALD (Atomic Layer Deposition)

OWN DESIGN LOCALLY MANUFACTURED

The Calibre Manufacture Morteau 30 (CMM.30) tourbillon unique’s design offers high performance thanks to its clever architecture and high-quality Franco-Swiss components. Entirely designed and developed by Olivier Mory in La Chaux-de-Fonds, the regulating organs are manufactured in Switzerland while the bridges and mainplates are manufactured by YEMA in its Morteau workshops.

FRANCO-SWISS ACCURACY

With its Swiss regulating part, the CMM.30 tourbillon is a high-precision movement ensuring high performance. The free-sprung balance wheel regulates isochronism for lasting precision and stability. In the absence of a regulator, the durability of the hairspring is increased, as is long-term precision. Adjusted in 6 positions, the CMM.30 ensures an accuracy of –3 and +7 seconds per day.

105 HOURS OF POWER RESERVE THANKS TO A LARGE BARREL

The CMM.30 has a single large barrel optimized to ensure a power reserve of 105 hours. Specifically manufactured for the CMM.30 by Générale Ressorts, this large barrel is off-centered in order to make enough room for the gears and the balance wheel so as to preserve a contained thickness.

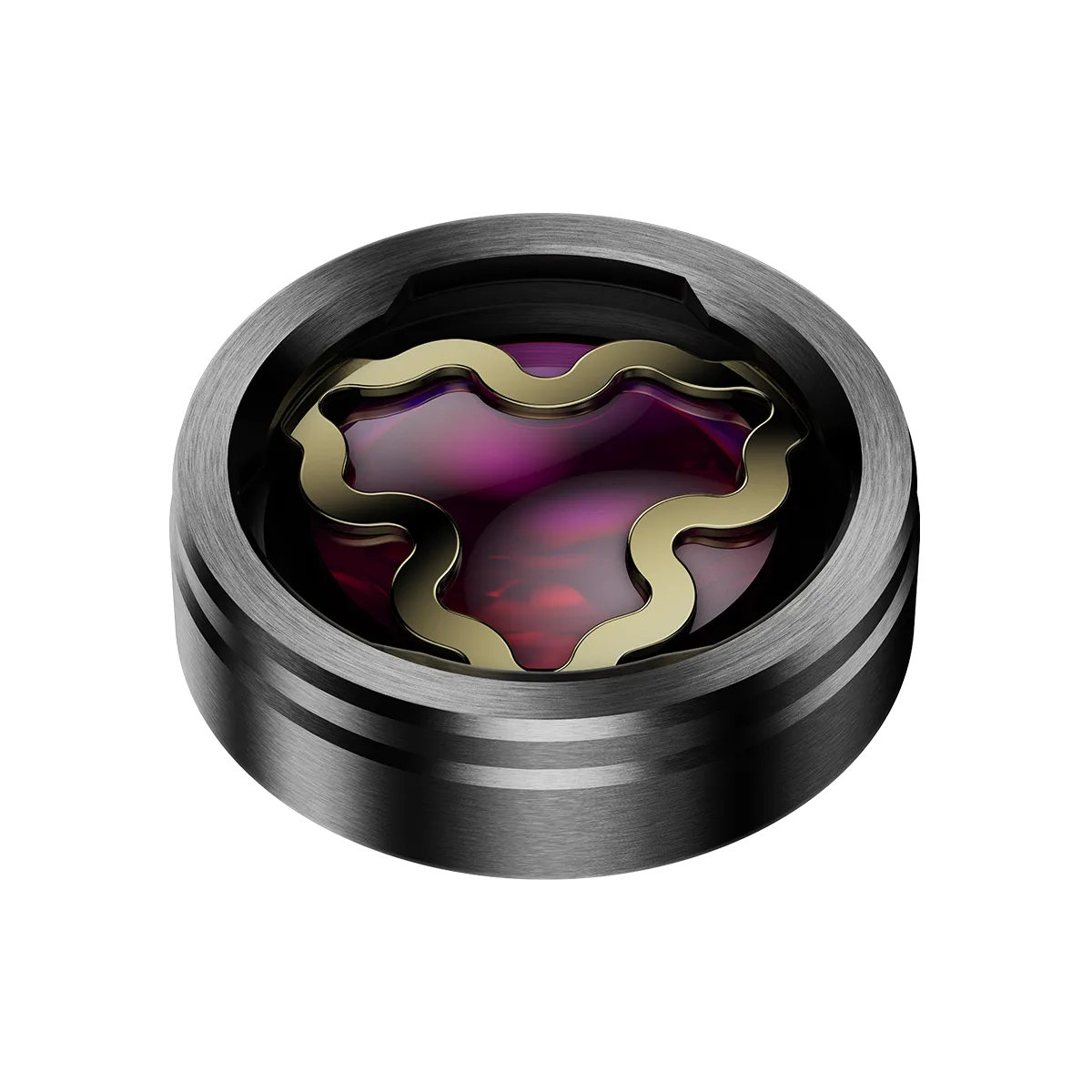

OPTIMIZED ESCAPEMENT

Interface between the gear train and the regulating organ, the escapement is the place where energy and chronometry intersect in a complex interaction. The escapement is an energy-demanding system, it alone consumes more than half of the barrels’ energy. It is the friction of the anchor pallets on the anchor which, despite their lubrication, dissipates a good part of this energy.

The CMM.30 tourbillon escapement presents notable improvements which reduce this friction thanks to an innovating and particularly sophisticated manufacturing process (LiGA technology). This advanced escapement ensures optimization of the entire mechanics, precision and longevity of the caliber components.

ANTI-MAGNETIC& SHOCK-RESISTANT

Designed for everyday life, the CMM.30 presents robust technical characteristics for a tourbillon caliber. Equipped with non-magnetic components, such as a Swiss-made non-metallic alloy hairspring, a Glucydur balance wheel with an adjustment mass made in gold and micro-components manufactured with LiGA technology materials, the CMM.30 is capable of withstanding exposures to electromagnetic fields up to 2,000 Gauss, a real feat for a tourbillon caliber.

The architecture of the tourbillon cage bridge with its free-sprung balance wheel and the shock absorbers manufactured by Kif make the CMM.30 impervious to shocks, vibrations, and acceleration up to 5,000 Gs in all directions.

ATOMIC LAYER DEPOSITION (ALD) DECORATION

Instead of the traditional “guilloché” decoration, the curved shape of the slightly skeletonized bridges, reminiscent of rising tide waves, privilege a minimalist, uniform and high-quality decoration in order to accentuate the contemporary aspect of our Manufacture tourbillon caliber.

The exceptional satin-finishing and micro-blasting treatment of the mainplate and bridges is carried out in black color using the latest ALD (Atomic Layer Deposition) technology by a renowned Swiss specialist in nanometric decorative coatings.

This revolutionary gas deposition process guarantees a uniform coating with a precision of approximately one nanometer, which preserves the decorative satin finish of the surface.

TALENTED FRENCH WATCHMAKERS TEAM

Four talented French watchmakers, cumulating over 120 years experience at the most prestigious watch brands, have taken up the challenge of creating YEMA’s first Manufacture Caliber

Olivier Mory

Watchmaker Developer

20+ years experience at Audemars Piguet, Sellita, Piaget, Cartier, Panerai, Skill, YEMA

Patrick Augerau

Senior Watchmaking Engineer

45+ years experience at Omega, Audemars Piguet, YEMA

Jean-Paul Boillot

Master Watchmaker

40+ years experience at YEMA

Nicolas Bailly

Technical Watchmaker

15+ years experience at Cartier, Pro Horlogerie, YEMA

YEMA'S IN-HOUSE WATCHMAKING MACHINING CENTER

During the last two years, YEMA has made substantial investments aimed at insourcing a good part of its production, constantly improving the quality of the manufacturing processes as well as developing a future range of French Manufacture calibers.

This significant development has required substantial R&D, new equipment and the expansion and modernization of our workshops and production lines. YEMA’s Manufacture Calibers benefit from improved precision and performance and will soon equip premium YEMA timepieces.

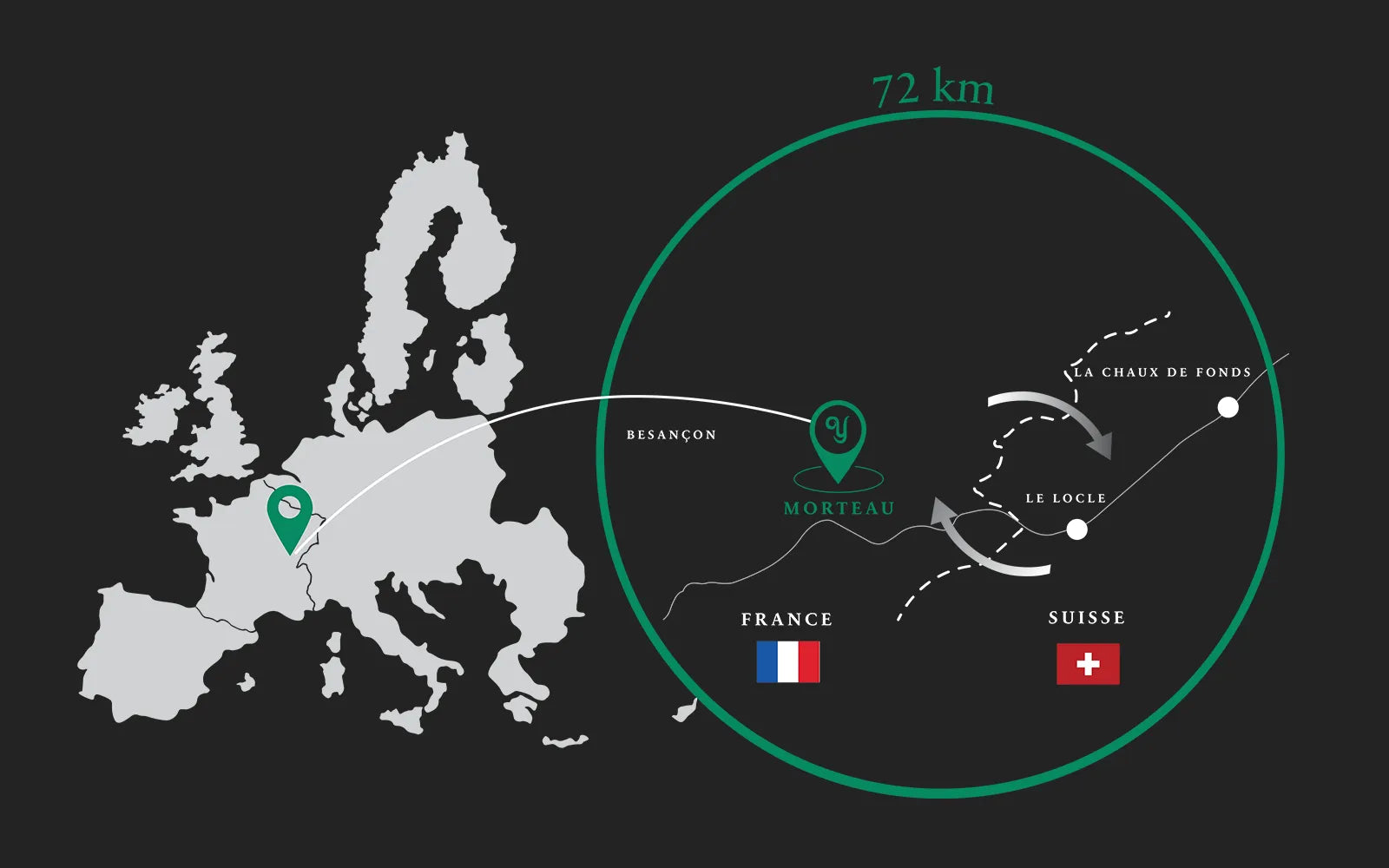

LOCAL PRODUCTION

Over the past few years, YEMA has made significant investments aimed at insourcing a good part of its production and constantly improving the quality of its manufacturing processes by implementing latest equipment as well as expanding and modernising its workshops and production lines.

In addition, YEMA now works with new local partners in France and Switzerland within a range of 72km of its workshops, to secure a more responsible and higher quality production.

Movement Components

All Manufacture movement components are manufactured in France and Switzerland within a range of 72km from Morteau by recognized craftsman in fine watchmaking. The caliber bridges and mainplates are manufactured in YEMA’s workshops in Morteau where final assembly of all components takes place.

COMPONENTS

ORIGINS

Movement Design

Switzerland

Movement Components

France + Switzerland

Assemblies

France

A DYNAMIC REGIONAL WATCHMAKING ECOSYSTEM

YEMA workshops are based in Morteau, the cradle of French watchmaking, a few steps from the Swiss watchmaking region. This cross-border watchmaking community concentrated along the Jura mountains has gradually transformed into a true regional ecosystem recognized as Intangible Cultural Heritage by the UNESCO in 2020.